Our strength:

High manufacturing competence for the fast and reliable supply of our customers with components of highest quality.

Spare part manufacturing

We can supply any replacement part, assembly or component you need for your gear unit with quick turnaround times. We can also advise you about setting up an individual stocking strategy for key functional parts for your gear units. You can fit our made-to-measure replacement parts so as to continue to use your legacy systems or you can equip your plant with higher-quality, longer-lasting components.

Engineering

Since technical systems experience permanent change, specialist knowledge is called for in many areas. To help relieve your workload in day-to-day business operations, we are happy to design bespoke gear unit models for your specific use case. Striving for the highest levels of performance whatever the field – rotordynamic analysis, API, AGMA, DIN or FEM – has made us the leading special gear unit manufacturer.

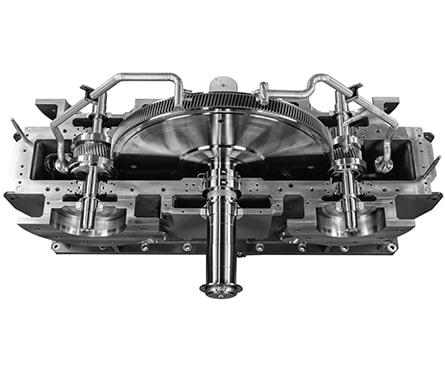

Reverse Engineering

Thanks to our decade-long engeneering and manufacturing experience and the latest mobile coordinate measuring technology we are able to manufacture wheel-sets in original quality with a diameter of up to 2 metres (also for turbo gearboxes with or without thrust collar) from all conceivable manufacturers like Flender-Graffenstaden, Lufkin, Atlas Copco, Renk, Maag, David Brown, etc.

Contract manufacturing

Use our specialist knowledge and high level of vertical integration for all of your contract manufacturing needs, and benefit from our efficiency and high quality. Our modern technical facilities are at your service for contract manufacturing of helical gears, bevel gears, complete gear stages, etc.

Knowledge transfer

We know how knowledge transfer works. In recent years, our in-depth know-how and expertise has been used to set up one of the largest production plants for special gear units in Latin America. We are also happy to provide you with our expertise as part of a contractual agreement.